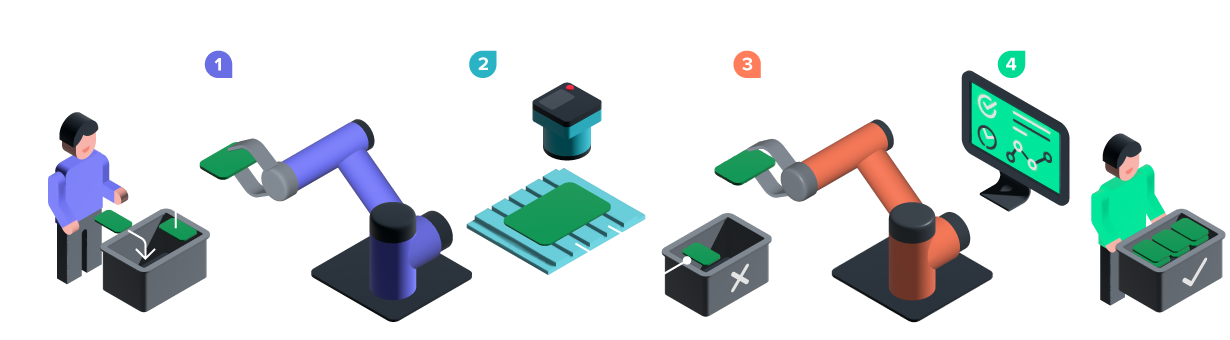

Take the first step into the world of ‘Dark Factory’. The robotic controller can work all night without the anyone’s help.

The robotic arm can remove products and parts from conveyors, KLT boxes, pallets, feeders or various containers.

Quality control is carried out without direct human assistance. It controls with the aid of intelligent cameras or special jigs.

It detects defective items and separates them from others. The storage location can be selected separately for each type of defect.

It processes accurate test results. In the spirit of Industry 4.0, it provides data to superior systems.

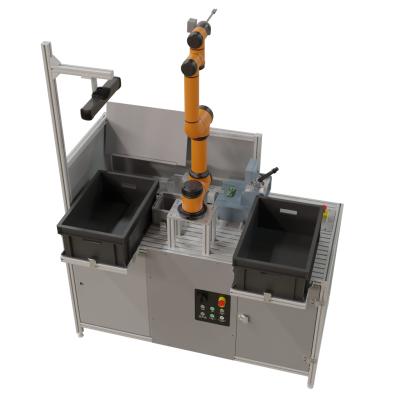

The robotic arm removes circuit boards from a KLT box, conveyor, CAB tray or pallet. It loads them into the ICT tester and discards the defective pieces after evaluation. The Test-it-off is an island solution that operates independently of the production line clock.

The system works non-stop and independently of people. It communicates automatically with other production nodes.

Changing the configuration for related products takes seconds, not hours.

The human factor does not enter into quality control. The evaluation is always objective.

It provides an absolute overview of the state of the work, including the traceability of results.

Automate quality control with the Test-it-off robotic system. It eliminates deficiencies created by human testing – working objectively, continuously and accurately.

Quality control takes place at a separate workplace outside the production cycle. Thanks to this, it is independent of the cycle and service intervals of the production nodes. You can easily test 100% of your production with Test-it-off.

The robot works autonomously and can handle both bulk products and parts. It communicates with other production nodes in the spirit of Industry 4.0.